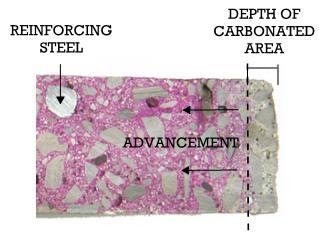

When evaluating the causes of deterioration in reinforced concrete structures, one of the commonly overlooked causes is carbonation. In reinforced concrete, this chemical process slowly and progressively advances inward from the exterior face of the concrete. When the depth of carbonation reaches the reinforcing steel, there are severe consequences that usually result in corrosion of the reinforcing steel. The corrosion causes the reinforcing steel it to expand and exert tremendous force on the concrete, creating fractures and/or spalls.

What is carbonation?

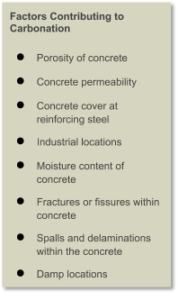

The carbonation of concrete is a reaction between environmental gases and the chemical constituents within the concrete. When carbon dioxide in the air diffuses into the concrete pores and reacts with water, it creates carbonic acid, which reacts with calcium hydroxide in the concrete to form the calcium carbonate. As a result of this reaction, the alkalinity of the concrete is reduced in the affected area. Moisture must be present for the reaction to take place, so it typically begins at the exterior and moves inward at a typical rate of about 1mm per year (in good concrete). Therefore, the rate of carbonation depends largely on the quality of the concrete, the condition of the concrete, the permeability of the concrete, and the presence of fractures or spalls.

What does it mean?

Normal concrete has a highly alkaline environment (pH level of 12-13). This high alkalinity protects the reinforcing steel from corrosion due to a passive oxide layer that forms on the surface of the steel. This protective layer remains stable in the highly alkaline environment, but not at lower pH levels. When carbonation occurs, the pH level of the concrete is lowered, and consequently, the protective layer over the steel is lost. When the steel is depassivated and the concrete has a low pH level, then corrosion will begin when moisture is introduced into the concrete.

What can we do about it?

We can stop the advancement of carbonation by preventing moisture from entering the concrete either through its surface or through cracks and spalls. The first line of defense is to repair any vulnerabilities on the surface such as cracks and spalls. Further protection is available with protective coatings that are applied after the surface is repaired and cleaned. As soon as a low concrete cover over at the reinforcing steel has been identified, it is important to take swift action before the carbonation reaches the reinforcing steel.

If you have fractures, spalls, or delaminations in your concrete please contact us for an evaluation. Even new concrete should be protected from the forces of carbonation. We would love to take a look at your structure and discuss options for preserving the life of the concrete.