When evaluating distressed concrete on aging structures, one useful resource is testing the concrete itself. Often this includes core sampling performed by the contractor in conjunction with an analysis that is performed by a certified laboratory. There are a number of tests that can be performed, but a basic series of testing can identify red flags which can indicate the causes of premature concrete failure.

Useful tests

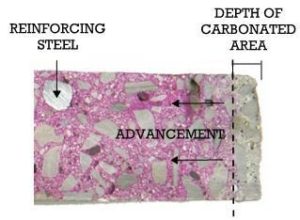

- Carbonation levels and pH levels in the concrete.

- Depth of carbonation advancement (if present).

- Micro-fractures and paste/aggregate bond.

- Coarse-aggregate bond strength

- Chloride-ion content analysis

- Estimated water-cement ratio at construction

- Air-entrainment content

- Compressive strength and concrete density

- Previous coatings that may have been applied or that are present

- Chemical attack on the concrete and depth of advancement (if any industrial or atmospheric gases are present)

Core extraction

Each core should be compared relative to one another and the results should be evaluated based upon their location in the structure and the type of structure. Careful attention should be given to choosing the locations for extracting cores so that a proper sample is taken. This should include consideration about areas of distress, elevation, height, previous coatings, and exposure to environmental elements or industrial contaminants. If possible, a stable control variable should be gathered as well. With any test, it is very important to keep a detailed record of the locations of each core so that the results can be correlated to back the structure.

Insights

The test results can give us insight into repair recommendations if the results are kept in context with the type of structure being examined. For example, if it is a concrete silo that was constructed utilizing a slip-form method, then the paste/aggregate bond may have micro-fractures because the forms are often moved before the concrete is fully cured. To expedite the curing so that they can move the forms, accelerators are often added into the concrete mix resulting in higher chloride-ion content. The elevated chloride content suggests that introducing moisture will cause corrosion, which may explain why shallow placed reinforcing steel is corroding at an advanced rate. In this example, we have evidence that a protective coating would be beneficial.

In another example, if the tests indicate that carbonation is present at a certain depth, then we can measure the rate of advancement of the carbonation based upon the age of the structure. If the depth of the reinforcing steel is verified or known, then we can predict how long it will take the carbonation to reach the reinforcing steel. In this example, a protective coating can help stop the carbonation from advancing toward the reinforcing steel if it is caught in time.

In another example, if the tests indicate that carbonation is present at a certain depth, then we can measure the rate of advancement of the carbonation based upon the age of the structure. If the depth of the reinforcing steel is verified or known, then we can predict how long it will take the carbonation to reach the reinforcing steel. In this example, a protective coating can help stop the carbonation from advancing toward the reinforcing steel if it is caught in time.

If you have a concern with the integrity of your concrete structure, please contact us for more information. Our team can assist with evaluating your structure and preparing recommendations.